Technical Parameters:

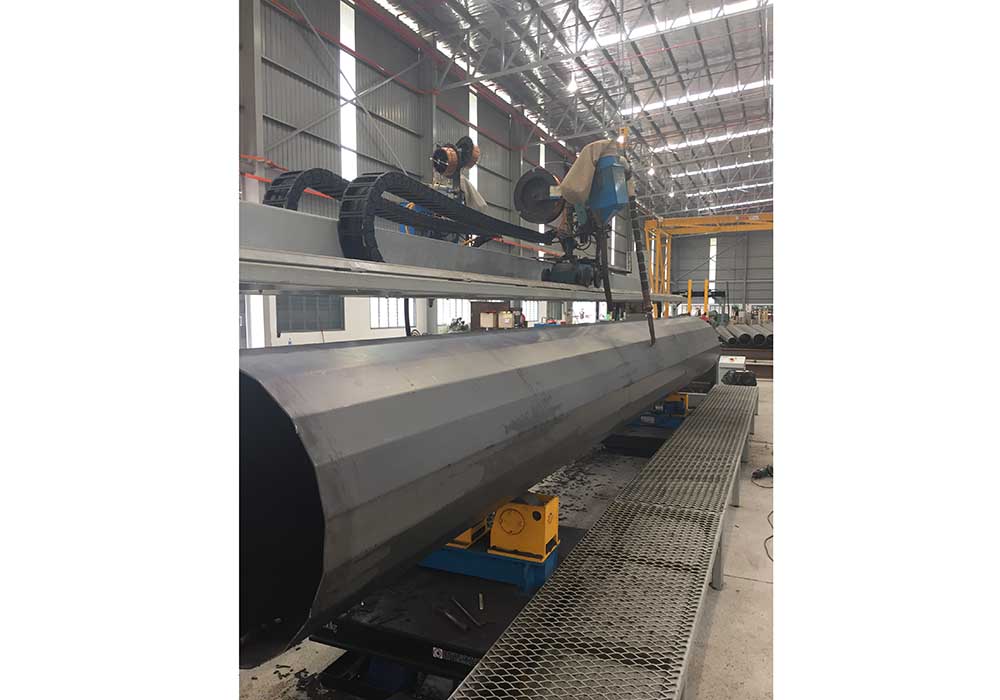

- Model: LMH-300

- Structure: Fix pole, Gantry walking

- Pole size: ɸ60-ɸ1500mm

- Gantry walking speed: 300-3000mm/min

- Walking motor: 0.37KW*2

- Arm up/down motor: 0.12KW

- Criss cross slider motor: 40W

- Criss cross slider stroke: L/R +/- 50mm, Up/down +/- 25mm

- Side cylinder size x stroke: ɸ80mmx150mm x2

- Upper cyinder size x stroke: ɸ80mm x100mm x2

- Elevator stroke x nos: 200mm x2

- Motor: 0.37KW

- Technical Parameters:

- V channel length: 7100mm