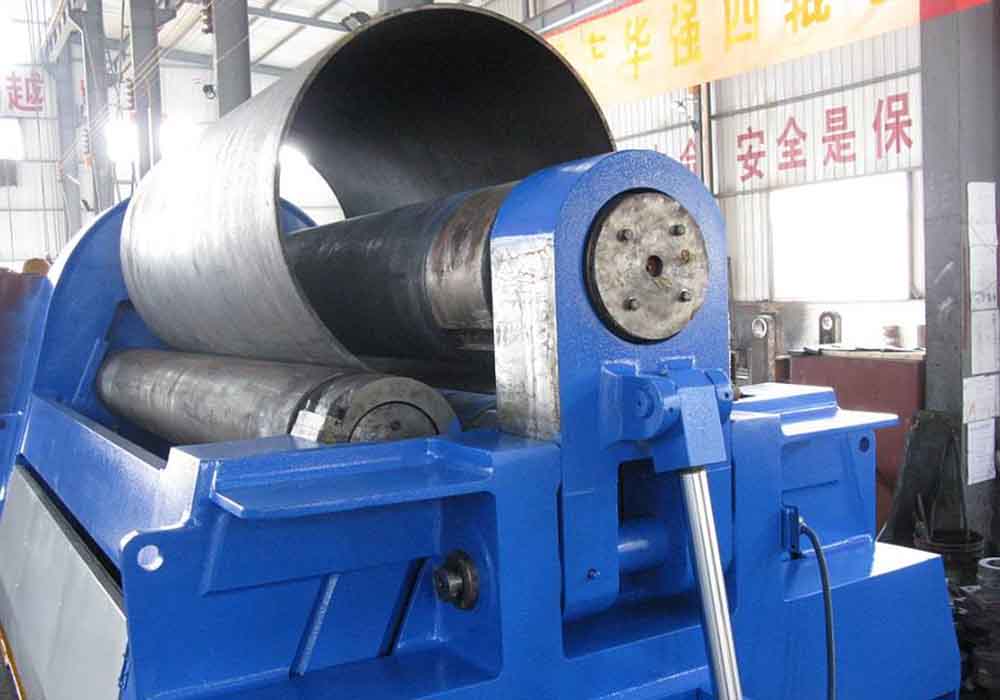

According to the adjustment of the position of the two sides of the roller arrangement can be symmetrical or asymmetric bending, so the machine can be rolled into a theoretical surplus straight edge is very small ideal cylinder, compared with the symmetrical three-roll coiler without the use of presses Pre-bending of the board side.

This machine under the roller, roller lifting displacement by the intelligent high-speed programmable logic controller PLC, automatic leveling, the screen digital display, synchronization accuracy ± 0.2mm.

This machine under the roll, side roll can be single-ended tilt, and can be tilted state with the same drop.

Equipment working conditions

Ambient temperature: -10 ℃ ~ 40 ℃.

Require the machine tool in the above working conditions, long-term stability.

Fully enclosed protective device is safe and reliable, machine tool safety should meet the latest national standards "General technical conditions for metal cutting safety and protection."